This week’s edition of Science has a special feature devoted to silicon and its use in electronics. As we reach the limits of what silicon-based transistors can do, the articles look not only at the the work being done by scientists to try give silicon new functionality, but also at the types of new materials which could replace it and how researchers are developing stretchable, flexible electronics.

This week’s edition of Science has a special feature devoted to silicon and its use in electronics. As we reach the limits of what silicon-based transistors can do, the articles look not only at the the work being done by scientists to try give silicon new functionality, but also at the types of new materials which could replace it and how researchers are developing stretchable, flexible electronics.

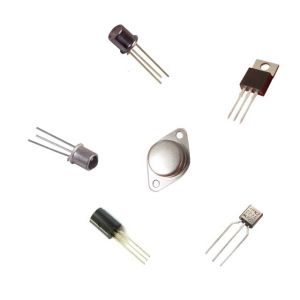

Silicon-based transistors are pivotal in the construction of electronics. These tiny little semiconductors, which replaced vacuum tubes, are used to amplify and switch electronic signals. Used in all modern electronics, one of the most important aspects of transistors is their ability to made in very high numbers, very easily and cheaply.

Silicon has historically been the material of which most transistors are made, but electronics manufacturers are beginning to run into a problem – we’re fast reaching the physical limits of transistors. One of the most visible impacts of this has been that computer manufacturers are no longer able to make computers which are actually faster than their predecessors (and haven’t for a few years) – they’re getting around this limitation by getting increasing numbers of processors to run in parallel (as opposed to simply using faster processors).

There are some tweaks and clever redesign options left to squeeze the last bit of out of silicon-based transistors, but scientists are having to look at alternatives – of these, transition metal oxides look to be very promising for a number of reasons, including the possibility that they could, in the future, be built at the nanoscale. And there is growing excitement about other options as well, such as complex oxide interfaces.

Of course, researchers are looking not only at how to improve the speed, and decrease the size and power consumption, of electronics – they are also working on how to change electronics’ form. Currently, electronics are generally rigid structures, but in the future this could change dramatically, with electronics that can change shape as they, or their user, need them to. A combination of being stretchy and flexible means that we could, one day, be able to wear our electronics, or even have them as implants!

The Science Media Centre asked some New Zealand experts for their views on electronics, both now and in the future.

Note: registered journalists can access the papers in the SMC Resource Library.

Professor Richard Blaikie, Deputy Director of the MacDiarmid Institute, comments:

“Modern silicon chips have dramatically changed the way the world works in the space of only 50 or 60 years, and the ‘electronics revolution’ is far from finished.

“This group of articles in this week’s Science magazine, from many of the leading groups worldwide, highlight the fact that there is still more speed, power and versatility to be obtained by further refining and controlling the structure and the behavior of silicon and other electronic materials. From printing circuits on plastic for roll-up displays, to working on materials that require exquisite orchestration of electrical, magnetic and even superconducting properties, we will see this research translated into new and better electronic products in the years ahead.

“New Zealand researchers have and continue to make important contributions in these areas, including:

- Jeff Tallon, Bob Buckley and their teams at Industrial Research Ltd for their work on superconducting oxide materials;

- Grant Williams (IRL), Joe Trodahl and Ben Ruck ( both at Victoria University) for work on highly-correlated electron systems, and new magnetic and electronic materials;

- Steve Durbin and Martin Allen (Canterbury University) for their work on nitride- and oxide-based semiconductors, including world-record performance for devices made from zinc oxide;

- Uli Zuelicke (Massey University), Alan Kaiser and Michele Governale (both at Victoria University) for their theoretical work on understanding how current (and magnetic ‘spin’) flows in electronic devices;

- Keith Gordon (Otago University), Justin Hodgkiss (Victoria University), Ashton Partridge (Massey University), Jadranka Travis-Sejdic and David Williams (Auckland University) for their contributions to ‘plastic’ electronics, for solar cells, environmental monitoring and medical diagnostics;

- Richard Blaikie and Maan Alkasisi (Canterbury University) for developing new methods for patterning (lithography) at the nano-scale, as is required for modern integrated electronic circuits;

- Simon Brown (Canterbury University) and Andreas Markwitz (GNS Science) for developing new ‘bottom up’ methods for making nano-scaled electronic devices.

“New Zealand companies are also major contributors to the electronics industry worldwide, or users of electronics in their products, including Rakon, Buckley Magnet Systems, Tait Electronics, Beaglehole Instruments, Allied Telesis Labs, Dynamic Controls, Next Window, F&P etc.”

Dr Natalie Plank, of the School of Physical and Chemical Sciences at Victoria University of Wellington comments:

“The special section on materials for electronics shows just how fast, exciting and revolutionary the field is. The articles describe some of the recent developments detailing the need for new materials and device architectures to allow for further advancement of the electronics workhorse – the transistor.

“One of the most exciting advancements in electronics is the current switch from rigid silicon substrates onto flexible substrates, such as Polydimethylsiloxane (PDMS). The astounding achievement of integrating nanometre wide ribbons of silicon, connected by flexible metal wires and carbon nanotubes will lead to a paradigm shift in the application of electronics. Not only do these advances lead us into a world of exciting and pleasing products, such as advanced mobile phones and integrated displays, combining nano electronics with conformal materials will lead to huge advances in the bio-diagnostics and the field of prosthetics.

“The channels and connections on these devices are by design on the nanoscale in order to achieve the required flexibility and as a consequence of the enhanced surface to volume ratio the electronic response is extremely sensitive to any environmental changes. The exceptional sensitivity, functionality and soft material environment looks set to revolutionise on the spot diagnostics and bioelectronics integration.”

Dr Martin Allen, of the Department of Electrical and Computer Engineering at the University of Canterbury, comments:

“The ability to keep fulfilling Moore’s Law – the doubling of integrated-circuit transistor density every two years – is clearly causing the semiconductor industry a few sleepless nights. Despite the interest in exotic new materials it is clear that “silicon with a twist” will continue to provide the backbone of continued performance increases at least in the short to medium term.

“Successful “twists” have included the replacement of SiO2 with new high-K (kappa) gate dielectrics and the use of metal gate electrodes in place of poly-Si. There is also increasing interest in integrating new high mobility channel materials such as Ge and III-IV compounds into Si circuitry. (Ref: Ultimate Scaling of CMOS Logic Devices with Ge and III-IV Materials, M. Heyns and W. Tsai, MRS Bulletin, Vol 34, pp 485-488, July 2009.)”

Further Information

To speak with experts quoted above or for other assistance, contact the Science Media Centre on tel: 04 499 5476 or email: smc@sciencemediacentre.co.nz.